This is an old revision of the document!

How To assemble and connect the optocoupler.

How to assemble and connect the Top Jaw.

ERRATUM the lightpipe Digikey number is 492-1291-ND and not 491-1291-ND

The lightpipe will be necessary to bring light for the hole detector…

This is to connect your LEDs to a computer power supply connector (of the same type as the old hard drive connectors, from the era of before the SATA drives)

The strips will have a tendency to dry and get loose over time, you should do small spots of hot glue on various corners, as long as you don't put glue over the leds themselves.

With a multimeter it's easy to figure out if two of the wires are of the same phase, it's when you can mesure a resistance value between them (at the condition that it is a 4 wires stepper motor. As long as you have the 2 phases connected it's not a big issue if the rotation is inverted as you can change its direction in the file hardwarecfg.json with the obvious setting “invert”, one for each of the 3 motors.

How to do the layout before gluing the pieces on a plank.

The layout does not need to be very precise, use the biggest reel you got to decide where to place the turntables.

The camera holder is not to be glued, you need to be able to move it around to adjust framing and focus.

For the other pieces you just need to add small smudges of hot glue on the corners.

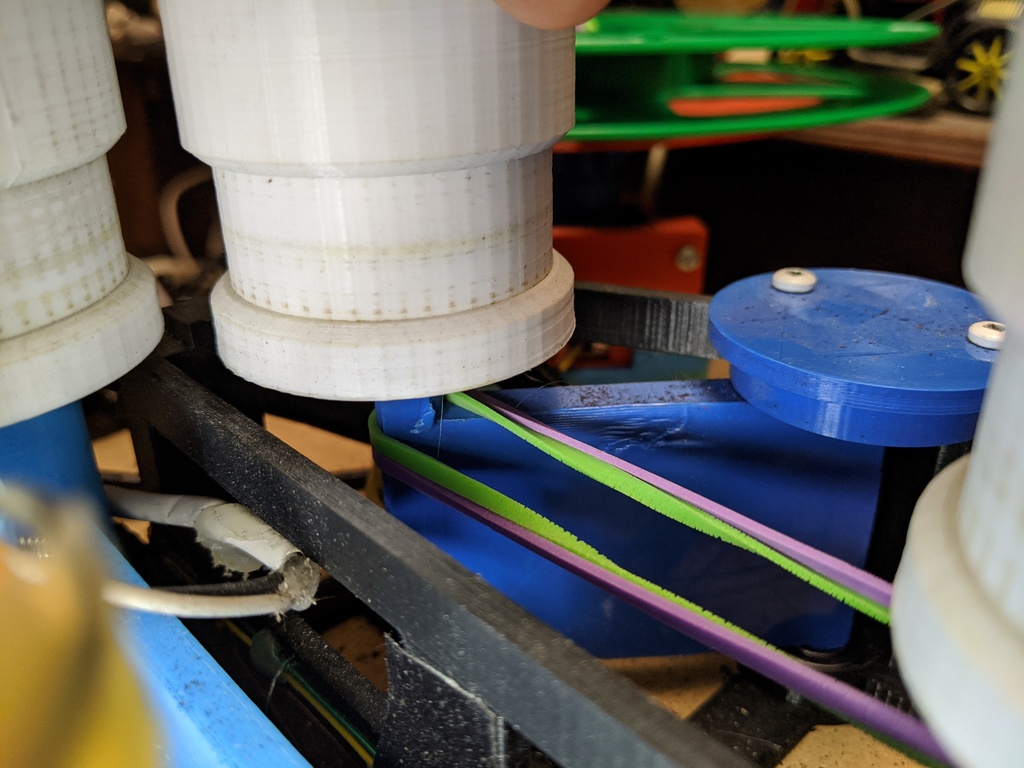

Using elastics

Common household elastics are at the very hearth of the Gugusse, to create the tension on the film the two swinging arm are pulled one to another with these. The film tension is directly related to the strength of the elastics themselves, it doesn't need to be much but not enough and the film will have issues advancing while too much and the film will be submitted to too much abrasive friction at the gate, when it won't simply break. Just place elastics to right under the rollers. An elastic varies its tension according to the distance that it is stretched, the distance they will be kept apart at all time is the distance between the 2 arms when they are each at their middle position.

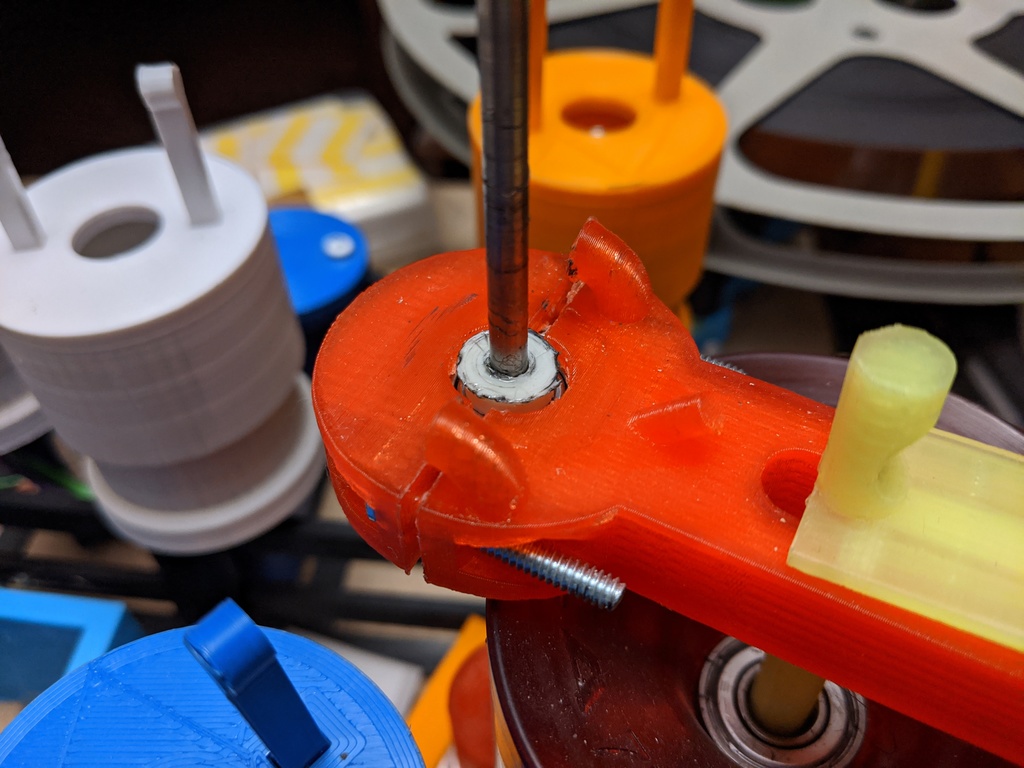

The idea here is just to pull the longboard wheel onto the small motor shaft. A small hook is there just to prevent the elastic to rub on the motor shaft. Again, it doesn't need to be strong, a small pressure suffices.

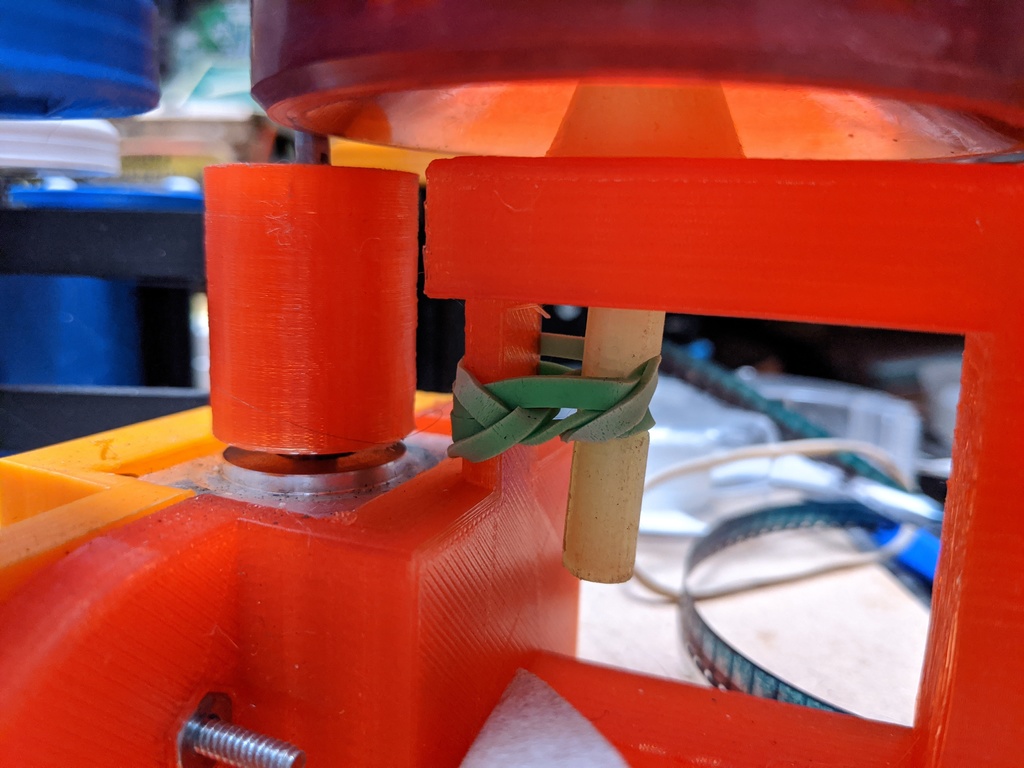

You'll also need an elastic under the wheel, this one is a bit tricky to install, you'll swear against the jester who designed that part…. Sorry… Be patient, you'll get it right.